Signed in as:

filler@godaddy.com

Signed in as:

filler@godaddy.com

Increasing material prices and higher quality demands to require full control of your extrusion lines. Movacolor offers this with our MCWeight throughput measurement system in the capacity range between 10-1,200 kg/h. The 8” full color touch screen controller can be connected directly to your extrusion line.

There are four control options:

Interfacing with extruders and pullers, as well as with central control systems, can be done with a wide variety of interfaces, whether analog or via several bus systems.

The extremely simple user interface allows your operators to run the extrusion lines with an absolute minimum of scrap within the tightest possible quality margins.

MCSmart monitors the performance of all gravimetric Movacolor systems controlled from one to unlimited number of touch screen controllers.

The system is based on a SQL database for 24/7 of data collection. Data can be retrieved at any time, even after months.

MCSmart can be installed as stand alone or a server/client application. Multiple desktop users can access the database. Available functions depend on used login level securing any risk of unintended use.

An unlimited reporting function for generating material consumption reports and alarm summary reports is at your disposal.

Connection is established via standard LAN network. The software can be installed on any standard PC, stand alone or in a central server configuration.

All recipes can be made and managed in this system. These recipes are synchronized to individual units and can either be activated locally or remote, taking away any possible operator mistakes.

The remote operation option allows you to duplicate the touch screen on your computer and perform all operations, as if you were in front of the unit.

Gravimetric Dosing systems that can be equipped with MCSmart Software

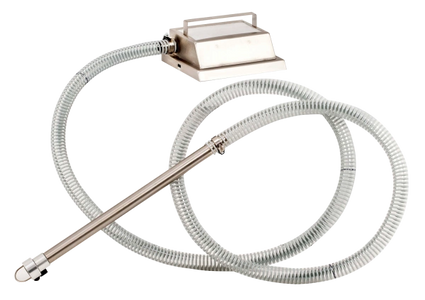

Movacolor Ejector (ME) compressed air Hopper Loader for granules can be fitted directly on to the 6 and 12 liter material hoppers. Maximum capacity 40 to 125 kg/h (material depending) Complete with hopper lid, dust filter, solenoid valve, material hose, Asens level sensor and suction probe.With the automatic Hopper Loader for masterbatch and regrind, the hopper will automatically be filled. This is an advantage because the gravimetric or volumetric dosing unit can never run out of masterbatch and/or regrind.The ME automatic filling system blows the material from the bag, drum or container into the hopper of the dosing system. The hopper lid of the housing has a simple and easy-to-clean dust filter to keep any dust particles in the hopper. The ME Hopper Loader is controlled by the electronics of the dosing unit.

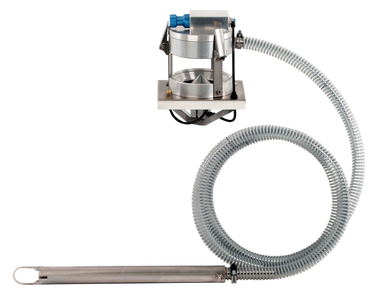

Movacolor Vacuum (MV) Hopper Loader for free flowing powders and/or granules. Complete with hopper lid, vacuum chamber with filter, compressed air solenoid valve, material hose, Asens level sensor and suction probe.The MV automatic Hopper Loader for free flowing powder and granules uses a three stage vacuum generator which is driven by compressed air to create a vacuum that brings material into a chamber. Once the chamber is filled with material the cone will open and the material will be discharged into the hopper.The system is equipped with a superior filter to ensure that the finest particles (> 5 micron) stay in the system and aren’t released into the atmosphere. This makes the MV Hopper Loader the most practical and user friendly system for both powders and granules.

Maximum capacity 30 to 120 kg/h. Complete with material hose and suction probe. This hopper loader can be fitted on a support frame or main material hopper. This Hopper Loader is also available with a brushless motor.

Maximum capacity 150 to 2,000 kg/h. Complete with material hose and suction probe. This Hopper Loader can be fitted directly on a support frame or main material hopper.

Files coming soon.

This website uses cookies. By continuing to use this site, you accept our use of cookies.